CRP101 - Digital Pressure Gauge - Accuracy up to 0.02% FS (Testing & Calibration) - electrical input channel as optional

CRP101 – Digital Pressure Gauge Inox, Accuracy up to 0.02% FS

Compact, with a large display and simple to use. The digital gauge CRP101 is suitable for the calibration and testing of pressure instruments such as analog gauges, digital pressure gauges, pressure transducers, pressure transmitters, pressure switches, etc. Configurable with a second channel for temperature measurements (RTD 4-wires) the CRP101 is the perfect salution for on-field calibration when combined with a dryblock IBL and hand-pump MVP-600 or M-10

Several models availabel depending on the range and accuracy requested

Specifications

• Accuracy up to 0.02 % FS pressure

• Pressure Resolution better than 0.001 % FS

• Temperature Resolution up to 0.001 °C

• Fully temperature compensated (14...122 °F / -10…50 °C)

• Data-logger

• RS232 Connection

• Ni-Mh rechargeable battery

• Measuring Fluid: Any fluid compatible with stainless steel

• Wetted part: Stainless Steel

• Case: Stainless Steel

Optional electrical input channel: RTD or 0...25 mA or 0...10 Vdc

Dimensions: Diam. 129 mm, thickness 47 mm

Weight: 0.5 kg

Warranty: 1 year, extendible to 24 months

Made in Italy

| Datasheet | Table | Manual |

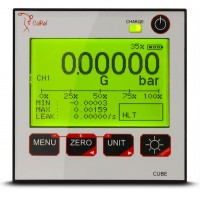

CUBE - High Accuracy Digital Pressure & Temperature Gauge

CUBE – Digital Pressure/Temperature indicator 2 channels

Compact, with a large display and simple to use. The digital meter CUBE is suitable for the calibration and testing of pressure instruments such as analog gauges, digital pressure gauges, pressure transducers, pressure transmitters, pressure switches, etc. Configurable with one or two channels each or both for pressure and/or temperature measurements.

Available Models:

CUBE-P - 1 Pressure Channel

CUBE-PP - 2 Pressure Channel

CUBE-T - 1 Temperature Channel RTD pt100 4w

CUBE-TT – 2 Temperature Channels RTD pt100 4w

CUBE-PT - 1 Pressure Channel and 1 Temperature Channel RTD pt100 4w

Several pressure ranges available – Environmental conditions typical ranges for P & T

Specifications

• Accuracy up to 0.02 % FS pressure

• Pressure Resolution better than 0.001 % FS

• Temperature Resolution up to 0.001 °C

• Fully temperature compensated (14...122 °F / -10…50 °C)

• Data-logger

• RS232 Connection

• Ni-Mh rechargeable battery

• Measuring Fluid: Any fluid compatible with stainless steel

• Wetted part: Stainless Steel

• Case: aluminum nickel-plated

Dimensions: 96 x 96 x 96 mm

Weight: 0.5 kg

Warranty: 1 year, extendible to 24 months

Made in Italy

| Datasheet | Table | Manual |

CUBE BOX-PR High Accuracy Pressure Calibrator

High Accuracy Pressure Calibrator

The calibrator CUBE BOX-PR is suitable for the calibration and testing of pressure instruments such as pneumatic and electronic transmitters, analog gauges, digital pressure gauges, pressure transducers, pressure switches, valves etc.

The integrated pneumatic sections allow you to generate the desired pressures in all situations encountered in the field and feed the pneumatic instruments

Specifications

• Accuracy up to 0.02 % FS pressure

• Pressure Resolution better than 0.001 % FS

• Fully temperature compensated (14...122 °F / -10…50 °C)

• Data-logger

• RS232 Connection

• Ni-Mh rechargeable battery

• Measuring Fluid: Any fluid compatible with stainless steel

• Wetted part: Stainless Steel

• 2 channels shown simultaneously

• Warranty: 1 year, extendible to 24 months

• 20 Engineering Units: mbar - bar – Pa – hPa – kPa – MPa – kg/cm2 – kg/m2 – mmHg – cmHg – mHg – mmH2O – cmH2O – mH2O – torr – atm – psi – inHg – inH2O – ftH2O (Hg@0 °C; H2O @ 4°C; patm=101325 Pa)

Made in Italy

| Datasheet | Manual |

CUBE BOX-P High Accuracy Pressure Calibrator

High Accuracy Pressure Calibrator

The calibrator CUBE BOX-P is suitable for the calibration and testing of pressure instruments such as pneumatic and electronic transmitters, analog gauges, digital pressure gauges, pressure transducers, pressure switches, valves etc.

The integrated pneumatic sections allow you to generate the desired pressures in the field and feed the pneumatic instruments.

Specifications

• Accuracy up to 0.02 % FS pressure

• Pressure Resolution better than 0.001 % FS

• Fully temperature compensated (14...122 °F / -10…50 °C)

• Data-logger

• RS232 Connection

• Ni-Mh rechargeable battery

• Measuring Fluid: Any fluid compatible with stainless steel

• Wetted part: Stainless Steel

• 2 channels shown simultaneously

• Warranty: 1 year, extendible to 24 months

• 20 Engineering Units: mbar - bar – Pa – hPa – kPa – MPa – kg/cm2 – kg/m2 – mmHg – cmHg – mHg – mmH2O – cmH2O – mH2O – torr – atm – psi – inHg – inH2O – ftH2O (Hg@0 °C; H2O @ 4°C; patm=101325 Pa)

Made in Italy

| Datasheet | Manual |

745 High Accuracy Laboratory Pressure Standard

The Model 745 Portable Transfer Standards provide the highest accuracy pressure measurements for laboratory and metrological applications. Digiquartz® Transducers cover 25 absolute and gauge pressure ranges up to 40,000 psi (276 MPa) with unsurpassed accuracy, reliability and stability. The new, simple, intuitive front-panel user interface and versatile functionality with the rear-panel RS-232 computer interface make the Model 745 the best choice for high performance pressure calibrations. APPLICATION AREAS: Metrology,

Aerospace,

Meteorology, Oceanography,

Energy, Exploration, Reference Barometers, Laboratory Instrumentation.

Technical specifications

Range: 19 Absolute Pressure Ranges

0-15 psia (0.1 MPa) to 0-40000 psia (276 MPa); 6 Gauge Pressure Ranges

0-15 psig (0.1 MPa) to 0-200 psig (1.38 MPa)

Resolution: 0.0001%

Accuracy: 0.008% Full Scale

Intuitive front panel menu system

Two-line display with menu selectable functions: Taring;

Engineering units;

Pressure bar graph;

Sensor temperature;

Password protection;

Rate of pressure change;

Resolution and sampling speed; Adjustable number of display digits; User choice of stored or external text.

Rack or panel mount capability

Enhanced RS-232 command set

110 V or 220 V ac adapter power

Multiple remote display capability

Free configuration and logging software

20 hours battery operation (4 AA size)

Overpressure: 1.2 times Full Scale

Operating temperature: 0 … 40 °C

Weight: 1.8 kg

Power supply: 6 … 25 V dc

NIST traceable

Made in USA

| Datasheet | Manual |

745-16B High Accuracy Barometric Standard

The Model 745 High Accuracy Barometric Standards provide the highest accuracy pressure measurements for laboratory and metrological applications. The new, simple, intuitive front-panel user interface and versatile functionality with the rear-panel RS-232 computer interface make the Model 745 the best choice for high performance pressure calibrations. APPLICATION AREAS: Metrology,

Aerospace,

Meteorology, Reference Barometers, Laboratory Instrumentation.

Technical Specifications:

Range: 500 … 1100 mbar (0.005… 0.11 MPa)

Resolution: 0.0001%

Accuracy: 0.08 hPa

Intuitive front panel menu system

Two-line display with menu selectable functions:Taring;

Engineering units;

Pressure bar graph;

Sensor temperature;

Password protection;

Rate of pressure change;

Resolution and sampling speed; Adjustable number of display digits; User choice of stored or external text.

Rack or panel mount capability

Enhanced RS-232 command set

110 V or 220 V ac adapter power

Multiple remote display capability

Free configuration and logging software

20 hours battery operation (4 AA size)

Overpressure: 1.2 times Full Scale

Operating temperature: 0 … 40 °C

Weight: 1.8 kg

Power supply: 6 … 25 V dc

NIST traceable

Made in USA

| Datasheet | Manual |

765 High Accuracy Portable Pressure Standard

The Model 765 Transfer Standards provide the highest accuracy pressure measurements for portable field applications. The integral Digiquartz® transducers cover absolute, gauge and differential pressure ranges up to 40000 psi (276 MPa).

The Model 765 is portable, easy to use, and fully self- contained in a rugged, compact case. Turn it on and immediately read the pressure values in any of nine user- selectable engineering units. APPLICATION AREAS: Metrology,

Aerospace,

Meteorology, Oceanography, Process Control,

Energy Exploration, Reference Barometers, Laboratory Instrumentation.

Technical Specifications:

Range: 19 Absolute Pressure Ranges

0-15 psia (0.1 MPa) to 0-40000 psia (276 MPa); 6 Gauge Pressure Ranges

0-15 psig (0.1 MPa) to 0-200 psig (1.38 MPa); 3 Differential Ranges 0 to 18 psid (0.12 MPa)

Resolution: 0.0001%

Accuracy: 0.008% Full Scale

Intuitive front panel menu system

Two-line display with menu selectable functions: Taring;

Engineering units;

Pressure bar graph;

Sensor temperature;

Password protection;

Rate of pressure change;

Resolution and sampling speed; Adjustable number of display digits; User choice of stored or external text.

Enhanced RS-232 command set

110 V or 220 V ac adapter power

Free configuration and logging software

Internal data logging - over 390000 data points

Enhanced remote control and command

User-defined outputs

USB and RS-232 interfaces

High and low pressure alarm points

Internal rechargeable battery or AC power

100-240 V ac universal power adapter

Battery status LED and display indicator

150 hours rechargeable battery operation

Easy upgrades to embedded software

Overpressure: 1.2 times Full Scale

Operating temperature: -20 … 50 °C or 0 … 40 °C

depending on the sensor Full Scale

Weight: 3.8 kg

Power requirement: 100-240 V ac, 47-63 Hz

NIST traceable

Made in USA

| Datasheet | Manual |

DPC 3800 – Automatic Pressure Controller

Pneumatic Pressure Controller

Automatic pressure controller for absolute, relative and differential pressures in gas media. Several ranges are available from vacuum up to 250 bar. Accuracies up to 0.01% FS for each range. Thanks to the Ethernet port more controllers can be connected in a network to manage complex situations (multiple fields, productions, etc.). The controller has an integrated web-server that can publish pages dedicated to the calibration or testing without the need to install additional software on individual PCs.

The DPC3800 is able to control the pressure in large volumes up to 50l.

Specifications

• Medium: air, nitrogen (other on request)

• Ranges relative (bar): -1...1; 0...2; -1...3; 0...5; -1...10; 0...20; -1...30; 0...60; -1...100

• Ranges absolute (bar): 0...1; 0...3; 0...10; 0...30

• Ranges differential (mbar): -30...30; -100...100; -300...300

• Connections: 1/8’’ G female, (option: Connection hose 6 mm)

• Communication: RS-232, Ethernet RJ-45, (optional: IEEE-488.2 or output 4-20 mA)

• Display: Color Touchscreen

• Weight: controller 7.0 kg (15 lb), hydraulic cabinet 45 kg (99 lb)

• Warranty: 1 year, extendible to 24 months

• Compatible with all manometers and calibrators

• Optional: software DynaCal for the calibration reports generation

• Compatible with LabVIEW®

Made in EU

| Datasheet | Manual

DPC 3800HD – Automatic High Pressure Controller

Hydraulic Pressure Controller

Automatic pressure controller for absolute, relative and differential pressures in liquid media. Three pressure ranges are available up to 1000 bar. Accuracies up to 0.01% FS for each range. Thanks to the Ethernet port more controllers can be connected in a network to manage complex situations (multiple fields, productions, etc.). The controller has an integrated web-server that can publish pages dedicated to the calibration or testing without the need to install additional software on individual PCs.

The DPC3800HD is able to control the pressure in large volumes.

We recommend to use the controller with the "hydraulic cabinet" (see datasheet)

Specifications

• Medium: water, oil (other on request)

• Ranges relative (bar) : 0...400; 0...600; 0...1000

• Connections: M 16x1.5 for high pressure (optional: quick connector G1/2)

• Communication: RS-232, Ethernet RJ-45, (optional: IEEE-488.2 or output 4-20 mA)

• Display: Color Touchscreen

• Weight: controller 7.0 kg (15 lb), hydraulic cabinet 45 kg (99 lb)

• Warranty: 1 year, extendible to 24 months

• Compatible with all manometers and calibrators

• Optional: software DynaCal for the calibration reports generation

• Compatible with LabVIEW®

Made in EU

| Datasheet | Manual |

HDWT-D Dual Piston Cylinder Pressure Balance up to 1200 bar

Hydraulic Pressure Balance (DWT)

The HDWT-D series is dedicated for laboratories that want to equip a primary reference for the measurement of pressure. The excellent repeatability, the absence of hysteresis, the low uncertainty of measurements (rdg) and the ability to stabilize the pressure, make these irreplaceable instrument for a wide range of applications.

The dual piston solution allows to obtain more extended measuring fields and therefore avoid changing the reference during the calibration of an instrument.

Specifications

• Medium: mineral or synthetic oil (depending on the model)

• Available models: HDWT-D-300; HDWT-D-600; HDWT-D-1200

• Range (bar): 1...60 + 5...300; 1...60 + 10...600; 1...60 + 60...1200

• Set of weights: Stainless steel available in bar, psi, kPa

• Uncertainty: 0.01% rdg (optional 0.008% rdg)

• Weight: base 20.0 kg (45 lb), set of weights 50 kg (110 lb)

• Warranty: 1 year, extendible to 24 months

Made in EU

| Datasheet |Manual |

PDWT - Pneumatic Pressure Balance up to 200 bar

Pneumatic Pressure Balance (DWT)

The PDWT series is dedicated for laboratories that want to equip a primary reference for the measurement of pressure. The excellent repeatability, the absence of hysteresis, the low uncertainty of measurements (rdg) and the ability to stabilize the pressure, make these irreplaceable instrument for a wide range of applications.

Specifications

• Medium: dry air or nitrogen

• Available models: PDWT-10; PDWT-60; PDWT-120; PDWT-200

• Range (bar): 0.15...10; 0.5...60; 1...120; 2.5...200

• Uncertainty: 0.01% rdg (optional 0.008% rdg)

• Set of weights: Stainless steel available in bar, psi, kPa

• Weight: base 20.0 kg (45 lb), set of weights 50 kg (110 lb)

• Warranty: 1 year, extendible to 24 months

Made in EU

| Datasheet | Manual |

HDWT HP -Pressure Balance up to 7000 bar

High Pressure Hydraulic Pressure Balance

The HDWT-HP series is dedicated for laboratories that need to generate high pressures. The new pressure balance HDWT-HP-7000 allows to generate and measure up to 7000 bar.

Available ranges:

40...7000 bar (4...700 MPa)

40...4000 bar (4...400 MPa)

40...3000 bar (4...300 MPa)

40...2500 bar (4...250 MPa)

40...2000 bar (4...200 MPa)

Specifications

• Medium: mineral or synthetic oil (depending on the model)

• Available models: HDWT-HP-7000; HDWT-HP-4000; HDWT-HP-3000; HDWT-HP-2500; HDWT-HP-2000

• Set of weights: (from 35 kg to 50 kg depending the model) Stainless steel available in bar, psi, kPa

• Hydraulic Connections: High Pressure

• Uncertainty: from 0.01% rdg to 0.05% rdg depending the model

• Weight: base 20.0 kg (45 lb), set of weights from 35 kg (75 lb) to 50 kg (110 lb) depending the model

• Warranty: 1 year, extendible to 24 months

Made in EU

| Datasheet | Manuale |

LPDWT Low Pressure Pneumatic Pressure Balance

Low Pressure Pneumatic Pressure Balance (DWT)

The LPDWT series is dedicated for laboratories that want to equip a primary reference for the measurement of pressure and vacuum. The excellent repeatability, the absence of hysteresis, the low uncertainty of measurements (rdg) and the ability to stabilize the pressure, make these irreplaceable instrument for a wide range of applications.

Specifications

• Medium: dry air or nitrogen

• Available models: PDWT-LP-1; PDWT-LP-V

• Range (mbar): 15...1000; -0.15...-900

• Uncertainty: 0.01% rdg (optional 0.008% rdg)

• Set of weights: Stainless steel available in bar, psi, kPa

• Weight: base 20.0 kg (45 lb), set of weights 50 kg (110 lb)

• Warranty: 1 year, extendible to 24 months<

Made in EU

| Datasheet | Manuale |

DGS Digital Pressure Gauge (ATEX Version available)

DGS is a micro-processor controlled, accurate and versatile digital pressure measuring instrument with integrated Max.-/Min.-function for calibration and testing purposes.

Range from – 1 to 1000 bar

Accuracy 0.05 % f.s. or better

Specifications

- Accuracy: (10…30 °C) 0,05 % f.s.

(including linearity, repeatability and hysteresis)

- Storage / Operating Temperature:10…60 °C /0…50 °C

- Compensated Temperature Range: 0…50 °C

- Supply: 3V battery, type CR 2430

- Battery Life: 2000 hours continuous operation “BAT LOW” warning on display

- Pressure Connection: 1/4” BSP M

- Protection: IP 65

- Diameter x Height x Depth: 76 x 118 x 42 mm

- Weight: 210 g

- Interface:RS485; rear-sided mating plug “Fisher” compatible with

PC-converter cable RS232 and USB IP65

Intrinsically safe version:

94/9/CE (ATEX) Avilable

- Classification: II2G EEx ia IIC T6

| Datasheet | Manual |

TM40 - Automatic Low Pressure Controller

Automaic Low Pressure Controller up to -250...250 Pa

Compact, with a large display and easy to use. Suitable for the calibration of low pressure instruments absolute, gauge or differential. 20 different selectable measuring units.

Application

Medical Technology, Pharmaceutical Industry, Chemical Industry e Petro-chemical, University and Research Laboratory, Diagnostic.

Specifications:

Accuracy: up to 0.05 % f.s.

Range: different ranges available (Gauge/Absolute/Differential)

Measuring units: 20 selectable

Interface: USB (Software Windows Optional)

Power Supply: 9Vdc + Internal battery Li-Ion 7.4V (8 hours)

Measuring fluid: air or inert gas

Weight: 4.5 kg

Warrantee: 1 year

Made in Switzerland

HM35 EX

Digital Pressure Manometer ATEX (Intrinsically Safe according ATEX.

Protection: EEx ia IIC T4). Measure of absolute/gauge/differential pressures.

Main functions: 22 selectable measuring units, MIN/MAX,

Pressure change rate, Average, data memory for 10’000 measurements, etc.

Via the infrared interface (IR), all data can be transferred directly to any PC

A communication software for Windows is also available.

Specifications

Media:

- inert gas or air for differential ranges

- all media which are compatible with stainless steel 18/8 (DIN 1.4305).

Range from 1 bar to 90 bar

Range: 16 different ranges are available from low range ( 0 … 25 mbar) up to 90 bar

Accuracy: up to 0,1 % rdg + 1 digit

Temperature: Compensated from 0 °C up to 50 °C

Humidity: max 95% RH

Display rate: 2M/s

Battery life time: 60 h

Pneumatic connection: Ø 4/6 NPT 1/8’’ (from 10 bar)

Case protection: IP 54

Dimension: 200 x 94/58 x 40/28

Weight: 0.3 kg

Warrantee: 1 year

Made in Switzerland

| Datasheet | Manual |

HM30

Meteo Station: pressure, humidity, temperature and altitude.

The Meteo Station HM30 is mainly use in the following applications:

Meteorology, Heating/ventilation /air conditioning, Geology, geodesy, Aviation, Mountaineering, Hospitals, Chemical and pharmaceutical industries. Compact, multi-function measuring Instrument for climatic data. Show simultaneously barometric pressure, two temperature and humidity.

Performance features

• Barometric pressure/ barometer/QNH

• Humidity/air temperature with combined sensor

• Second temperature with insertion sensor

• Dewpoint determination

• Altitude measurement

• Difference measurement

• Trend indication

• Peak value storage, max/min

• Hold and zoom function

• RS232 interface

• Connection for plug-in mains supply unit

• Battery voltage indication

• Splash-proof ABS case (IP54)

Specifications

Barometric Pressure: 225 …1125 hPa abs

Pressure resolution: 0,1 hPa

Accuracy (pressure): ± 1 hPa ± 1 digit

Relative Humidity: 0 … 100%

Humidity resolution: 0,1% RH

Accuracy (humidity): ±1,5% RH ± 1 digit

Temperature: S1: -40 … +60 °C /S2: -50 … 200 °C

Temperature resolution: 0,1 °C

Accuracy (temperature): ± 0,3 °C ± 1 digit

Altitude: -500 … 10000 m

Altitude resolution: 1 m

Accuracy (altitude): ± 10 m ± 1 digit

± 2 m ± 1 digit (Δ < 500 m)

Case protection: IP 54

Dimension: 152 x 83 x 34/29 mm

Weight: 0.27 kg + 0.18 kg for the sensors

Warrantee: 1 year

Made in Switzerland

HM28

Low Pressure Digital Manometer.

Compact, with a large display and easy to use.

Suitable for the calibration of low pressure instruments absolute, gauge or differential.

Leak rate function. Max/min. The measured values can be stored in the integrated data memory with the datalogger function and from there, logged directly on a connected printer (without PC) via the RS232 interface. A PC-software for Windows is also available.

Specifications

Accuracy: up to 0.05 % f.s.

Range: 0…25 mbar; 0…70 mbar; 0…200 mbar; 0…300 mbar; 0…500 mbar; 0…1000 mbar; 0…2000 mbar;

0…7 bar; 0…10 bar; 0…17 bar; 0…30 bar; 0…70 bar; 0…90 bar; 0…110 mbar abs; 0…2000 mbar abs; 0…7 bar abs

Measuring rate (RS-232): up to 20 readings/s

Measuring fluid: air or inert gas

Pneumatic connection: Ø 4/6 NPT 1/8’’ (from 10 bar)

Case protection: IP 54

Dimension: 152 x 83 x 34/29 mm

Weight: 0.27 kg

Warrantee: 1 year

Made in Switzerland

HM38

Pressure Calibrator

The pressure calibrator HM38 provides the user with two individual pressure measuring ranges for over- and under-pressure, differential or absolute pressure. It is possible simultaneously to measure and generate current and voltage. The illuminated display and the zoom function permit simple reading of the measured values. And of course with a datalogging function with interface RS232 and PC-software level Windows.

Further functions: measure/generate, leak rate, record, rampe, deviation, simulation and trigger.

Specifications

Pressure

Measuring fluid: inert gas or instrument air / for 30/70 bar versions all media which are compatible with stainless steel 18/8 (DIN 1.4305).

Range: 15 different ranges available. From low pressure (0 …25 mbar) up to 70 bar

Pressure resolution: up to 0,001 mbar

Accuracy (pressure): up to 0,05 % fs + 1 digit

Measuring units: mbar, bar, kPa, hPa, MPa, mmH20, mH20, mmHg, psi, inH20, inHg

Direct Current Measure

Range: 0…24 mA dc

Resolution: 1 μA

Accuracy: 0,025 % fs + 1 digit

Direct Current Generation

Range: 0…24 mA dc

Resolution: 1 μA

Accuracy: 0,05 % fs + 1 digit

DC Voltage Measure

Range: 0…30 V dc

Resolution: 1 mV

Accuracy: 0,025 % fs + 1 digit

DC Voltage Generation

Range: 0…1 V dc

Resolution: 0,1 mV

Accuracy: 0,05 % fs + 1 digit

Operating temperature: -5…50 °C;

Calibration temperature: 10…35 °C

Temperature effects: ≤ 70 mbar 0,02%/°C

≥ 200 mbar 0,005%/°C

Measuring rate (RS 232): 25 readings/s

Current consumption: < 30 mA w/o generation

Power Supply: 9 V battery or power supply unit

Memory: manual, 1…99 s/min/h selectable

Plugs: 4 mm, gold-plated

Pneumatic connection: hose Ø 4/6, NPT 1/8’’ female > 7 bar

Case Protection: IP 54

Dimension: 152 x 83 x 34/29 mm

Weight (incl. Battery): 0.3 kg

Warrantee: 1 year

Made in Switzerland

| Datasheet | Manual |

Hand-Held Pressure Measuring Gauge CR Series

The best quality-cost benefit available in the market. The CR Series has a large configuration possibility

Features

• Ranges from -1000 mbar up to 1000 bar

• Accuracy: up to ± 0,1 % f.s. ± 1 digit (at temperature = 25ºC) including linearity, repeatability and hysteresis

• 4 ½ digits large display, higher resolution available depending on the probe connected.

• Peak value memory 1000 measurements / s.

• Available models with data-logger & analogue output 0-1 V.

• 1 or 2 sensors depending on the model

• Transducers for air and non aggressive gases available

• Tare function

• Min/Max pressure value

• Barometric option available

• RS232 or USB connection

Dimensions (L x W x H): 142 x 71 x 26 mm

Weight: 0.2 kg

Warranty: 1 year

Made in EU

| Datasheet | Manual |

Waterproof Hand-Held Pressure Measuring Gauge CRS Series

The best quality-cost benefit available in the market. The CRS Series has a large configuration possibility.

Features

• Waterproof design

• Ranges from -1000 mbar up to 1000 bar

• Accuracy: up to ± 0,1 % f.s. ± 1 digit

• 4 ½ digits large display 7 segment, illuminated white.

• 4 measurements / s or 1000 measurements / s with peak value.

• Available models with data-logger & analogue output 0-1 V.

• 1 or 2 sensors depending on the model

• Transducers for air and non aggressive gases available

• Tare function

• Min/Max pressure value

• Barometric option available

• USB connection

• Measuring unit:

mbar – bar – Pa – kPa – MPa – mmHg –mH2O – psi – inHg

Dimensions (L x W x H): 160 x 86 x 37 mm

Weight: 0.2 kg

Warranty: 1 year

Made in UE

| Datasheet | Manual |

PK1 Pressure Kit for on-field pressure calibration

PK1 is a pressure calibration kit that include everything the operator needs to calibrate pressure instruments:

Specifications

- Pressure pump (four different models available)

- Manometer (Analog or Digital. More than 20 ranges available)

· Ranges: from -0.9 up to 700 bar

· Accuracy up to 0.02 % FS

- Hose

- Adapters

- Case (P67 conform to: Directive 2002/95/EC; CEI EN 60529 (1997) + A1 (2000); DS 81-41

(PART 3) with severity level NATO 1 & 2 e Military J; STANG 4280 (ed. 2) dated 1999-02-08)

Made in Italy

| Datasheet | Manual |

MGC - Manual Gas Comparator

The MGC Pressure Comparator is used to generate and control accurately pneumatic pressures up to 200. The main applications in which it is used are:

Pressure instruments calibration.

Pressure instruments testing

Valves testing

Available Models

MGC1 -0.9...200 bar

MGC2 -0.9...200 bar

The model MGC2 is more accurate and the hand wheel regulation does not change its position during use.

The MGC1 model has a hand wheel which advances and retreats according to the direction of rotation (classical screw).

Pressure input required

For controlling the negative pressures, a vacuum pump is required

Specifications

• Medium: Dry air or Nitrogen (other gases on request)

• Range (bar): -0.9...200 bar

• Connections: G1/2 (manual locking)

• Weight: base 15.0 kg (35 lb)

• Warranty: 1 year, extendible to 24 months

Made in EU

| Datasheet | Manual |

MGPC400 – Pressure Comparator (gas) 400 bar

High Pressure Pneumatic Comparator

The MGPC400 Pressure Comparator is used to generate and control accurate pneumatic pressures up to 400 bar. The main applications in which it is used are:

Pressure instruments calibration

Pressure instruments testing

Valves testing

Available model:

MGPC400 0.95...400 bar (0.095...40 MPa)

High pressure input required (booster)

Specifications

• Medium: Dry air or Nitrogen (other gases on request)

• Range (bar): 0.95...400 bar

• Connections: G1/4"

• Dimensions: rack 19" - 4U

• Weight: base 10.0 kg (22 lb)

• Warranty: 1 year

Made in EU

| Datasheet | Manual |

HPG2 – Hydraulic Pressure Comparator/Generator

Hydraulic Pressure Comparator

The HPG2 Pressure Comparator is used to generate and control accurate hydraulic pressures up to 7000 bar. The main applications in which it is used are::

• Pressure instruments calibration

• Pressure instruments testing

• Valves testing

Available models:

• HPG2-1250 0...1250 bar

• HPG2-2000 0...2000 bar

• HPG2-4000 0...4000 bar

• HPG2-7000 0...7000 bar

Specifications

• Medium: mineral or synthetic oil (depending on the model)

• Range (bar) : 1250; 2000; 4000; 7000

• Connections: G1/2" (Manual lock)

• Weight: base 15.0 kg (35 lb)

• Warranty: 1 year, extendible to 24 months

Made in EU

| Datasheet | Manual |

MPV 600

Produces pneumatic pressure and vacuum to check calibration of gauges, switches, transmitters, and recorders. The

contoured cushioned handles provide extra comfort while preventing the pump from sliding. The oversized check valve

provides smooth operation throughout the output range while the dual o-rings on all pistons ensure zero leakage.

Patented Mash proof vent valve comes standard on all MVP-600s (No Needle Valve) and a non-oil based lubricant is

used on all moving parts.

Specifications

Media: Air and compatible gases only

Range: Vacuum to Pressure (28"Hg - 600 PSI / 40 bar)

Connections: 1/4" NPT/BSP (top) & 1/8” NPT/BSP (side)

Materials: Stainless steel fittings, anodized aluminum housing, plastic/rubber handles, nitrile o-rings.

Weight: 0.91 kg

Made in the USA.

| Datasheet | Manual |

M-10

Utilizes a fully adjustable stroke control to allow for quick priming, easy pumping, and fast

pressure generation up to 700 bar. The ergonomically engineered handles provide extra

comfort, while the patented triple filtration system ensures pump operation in spite of dirty

conditions. The shatterproof reservoir and stainless steel construction guarantee leak free

operation. The pump has over-sized check valves to provide smooth controlled operation.

Specifications

Range: 0-700 bar

Connections: Gauge - 3/8" BPT, Process - 1/4” BSP (two 1/4“ NPT adapters included).

Materials: Stainless steel fittings, polyurethane, anodized aluminum housing, plastic/rubber

handles, PTFE, nitrile o-rings.

Weight: 1.36 kg

Compatible with all gauges and calibrators.

Made in the USA

| Datasheet | Manual |

M-80

Capable of extremely high resolution (1 Pa) as it spans the range of near absolute vacuum to low pressures (-1… 5 bar). It's rugged outer housing and dual o-ring design ensures zero leakage. Not only is the M-80 bench mountable, but it’s relative light weight (1-6 kg) makes it perfect for field use as well. Optional power drive supplied to rotate the vernier at a quicker pace in-order to speed up your calibrations.

Specifications

Resolution: 1 Pa

Range: -1 to 5 bar

Connections: Two 1/8" NPT female ports (gauge & Process)

Materials: Delrin® plastic handle, nitrile o-rings, brass, aluminum, polycarbonate.

Weight: 1.6 kg

Compatible with all gauges and calibrators.

Made in the USA

| Datasheet | Manual |

MP P

Features a Delrin® plastic handle that prevents body heat transfer from interfering with readings, as well as an oversized check valve for smooth operation. The dual o-rings on all pistons ensure zero leakage. It uses a “Schrader” valve which totally eliminates failure caused by the vent valve failing. The unique hose and fittings are push-on, and a swivel keeps the hose from tangling. If the hose is damaged simply cut off the end and reinsert it into the fitting. A special non-dispersing lubricant makes the first stroke as easy as the others, and eliminates wear caused by the grease migrating to the ends of the stroke. Construction is so strong that the Magnum pumps can be repeatedly dropped on a concrete floor without damage.

Specifications

Range: 0…7 bar

Connections: Two 1/8" NPT female ports (gauge & Process)

(one removable plug, hose and 1/4” NPT female included)

Materials: Delrin® plastic handle, nitrile o-rings.

Weight: 0.68 kg

Compatible with all gauges and calibrators.

Made in the USA

| Datasheet | Manual |

MP V

Features a Delrin® plastic handle that prevents body heat transfer from interfering with readings, as well as an oversized check valve for smooth operation. The dual o-rings on all pistons ensure zero leakage. It uses a “Schrader” valve which totally eliminates failure caused by the vent valve failing. The unique hose and fittings are push-on, and a swivel keeps the hose from tangling. If the hose is damaged simply cut off the end and reinsert it into the fitting. A special non-dispersing lubricant makes the first stroke as easy as the others, and eliminates wear caused by the grease migrating to the ends of the stroke. Construction is so strong that the Magnum pumps can be repeatedly dropped on a concrete floor without damage.

Specifications

Range: 0…-1 bar

Connections: Two 1/8" NPT female ports (gauge & Process)

(one removable plug, hose and 1/4” NPT female included)

Materials: Delrin® plastic handle, nitrile o-rings.

Weight: 0.68 kg

Compatible with all gauges and calibrators.

Made in the USA

| Datasheet | Manual |

MTG02 5314

Budenberg Standard Test Gauges are generally recognised as a world leader for accuracy and quality and are used by many Calibration Laboratories and workshops worldwide. The 5314 now provides a higher specification and incorporates many additional features as standard. Housed in a new die cast safety pattern case, the 5314 meets

the full requirements of EN837 including a brighter anti-parallax mirror scale & knife edge pointer for accurate repeatable readings. Recalibration is simplified by inclusion of a micrometer adjustable pointer and printed calibration marks on the dials. All units are supplied with a detailed calibration certificate which is traceable to National Standards.

Specifications

Sizes: 250mm dial diameter

Mounting : Direct, Surface Mounting

Flush Panel Mounting with clamp or three hole fixing

Case: LM6M Aluminium casting to BS1490 utilising a full Safety Pattern solid baffle

wall with blow out back, finish to BS381C

Bezel: Direct / Surface mount - Stainless Steel 316L polished. Flush mount - Die cast Aluminium finished in black.

Scale Ranges: 0 to 600 mbar up to 0 to 2500 bar Pressure Equivalent units of Pressure / Vacuum Available Dual Scale units or custom scales can be provided

Pressure Element: Up to 70 bar Beryllium Copper bourdon tube & Brass Chrome plated connection

From 71 bar up to 600 bar Beryllium Copper coil tube & Brass Chrome plated connection

From 601 bar up to 2500 bar Ni-Span C Coil & Stainless Steel connection

Option for Stainless Steel on request.

Accuracy Class: 0.2% of FSD as defined in EN837-1

Dial: White anodised Aluminium with Mirror Scale with Anti Parallax mirror scale for accurate reading.

Option: Dual scales or special dial markings are available

Pointer: Micrometer Adjustable, Knife-edge, Stainless Steel coloured Blac

Movement: Non Ferrous with Glass Bearings for Improved Accuracy & Sensitivity

Window: Safety window

Environmental Rating: Dust Proof and Splash Proof to IP54

Temperature: Operating: -20 to +60 Degrees C

Storage: -40 up to + 70 Degrees C

Options: For lower or higher operating temperatures, please contact our Sales Office.

Certification: All instruments are individually calibrated and have an unique Serial Number printed on the dial. A Certificate of Conformity traceable to National Standards is supplied free of charge.

Made in UK

STG015 5414

Budenberg Standard Test Gauges are generally recognised as a world leader for accuracy and quality and are used by many Calibration Laboratories and workshops worldwide. The 5414 now provides a higher specification and incorporates many additional features as standard. Housed in a new die cast safety pattern case, the 5414 meets

the full requirements of EN837 including a brighter anti-parallax mirror scale & knife edge pointer for accurate repeatable readings. Recalibration is simplified by inclusion of a micrometer adjustable pointer and printed calibration marks on the dials. All units are supplied with a detailed calibration certificate which is traceable to National Standards.

Specifications

Sizes: 250mm dial diameter

Mounting : Direct, Surface Mounting

Flush Panel Mounting with clamp or three hole fixing

Case: LM6M Aluminium casting to BS1490 utilising a full Safety Pattern solid baffle wall with blow out back, finish to BS381C

Bezel: Direct / Surface mount - Stainless Steel 316L polished. Flush mount - Die cast Aluminium finished in black.

Scale Ranges: 0 to 1 Bar up to 0 to 400 Bar Pressure

Equivalent units of Pressure / Vacuum Available

Dual Scale units or custom scales can be provided, contact our Sales Department with your requirements.

Pressure Element: Up to 70 Bar Beryllium Copper bourdon tube & Brass Chrome plated connection

From 71 Bar up to 400 Bar Beryllium Copper coil tube & Brass Chrome plated connection

Accuracy Class: 0.15% of FSD as defined in EN837-1

Dial: White anodised Aluminium with Mirror Scale with Anti Parallax mirror scale for accurate reading.

Option: Dual scales or special dial markings are available

Pointer: Micrometer Adjustable, Knife-edge, Stainless Steel coloured Black

Movement: Non Ferrous with Glass Bearings for Improved Accuracy & Sensitivity

Window: Safety window

Environmental Rating : Dust Proof and Splash Proof to IP54

Temperature: Operating: -20 to +60 Degrees C

Storage: -40 up to + 70 Degrees C

Options: For lower or higher operating temperatures, please contact our Sales Office.

Certification: All instruments are individually calibrated and have an unique Serial Number printed on the dial. A Certificate of Conformity traceable to National Standards is supplied free of charge.

Pressure connection: 1/2” BSP or NPT

3/8” BSP or 1/2” NPT as Standard on Flush Mounting Units Other connections including HF2 high pressure are available contact our Sales Office for Details

Made in UK

6000-RS-232 and RS-485 Output Pressure Transmitters

6000 Intelligent Transmitters consist of a Digiquartz® pressure transducer and a digital interface board in an integral package. Commands and data requests are sent via two-way RS-232 or RS-485 serial interfaces. Digital outputs are provided directly in engineering units with typical accuracy of 0.01% over a wide temperature range. Output pressure is fully thermally compensated using a quartz crystal temperature signal. All intelligent transmitters are preprogrammed with calibration coefficients for full plug-in interchangeability.

Technical Specifications:

Ranges Available: 10 Absolute Pressure Ranges: From 0-15 psia (0.10 MPa) to 0-500 psia (3.45 MPa).

6 Gauge Pressure Ranges:From 0-15 psig (0.10 MPa) to 0-200 psig (1.38 MPa)

Accuracy: 0.01 % Full Scale

Typical resolution: 1 ppm

Engineering units: 8 standards or User-defined

Operating temperature range: -54 … +60 °C (barometric range) / -54 … 70 °C Other Ranges

Overpressure: up to 1.2 times Full Scale (depend on the range)

Miniaturized Integral Microprocessor Electronics

Digiquartz® Transducer with Integral Shock Mount

Fully Temperature Compensated and Linearized Outputs

Dual RS-232 and RS-485 Interface

Baud Rate Selection: 300 to 115200

User Selectable Parameters Include:

Resolution, Sample Rate, Engineering Units, Integration Time, Sampling Commands, Software Recalibration Features, and Baud Rate

Compatible with the Model 715 Display

Weight: 450 g.

Prodotto in USA

CLEAN G - Cleaning Gauges Bench

Cleaning Gauges and Transducers Bench

The CLEANG system allows to clean easily pressure gauges, transmitters and transducers, eliminating the contaminated fluid and eventually replacing it with another clean fluid.

Two separated reservoirs for the fluid to be removed and for the new fluid and a valves system enables to perform the operation fast, easily and secure.

Pressure inlet needed (Max 7 bar).

Application

Cleaning the gauges before to be connected to the calibration system where are standards as pressure controllers DPC3800, digital indicators CUBE or pressure balances HDWT or PDWT.

Made in EU

| Datasheet | Manual |

KRAC-F-x – Quick Connectors Kit

Kit composed of 4/5 quick connectors with manual tightening

Quick connectors kit for low, medium and high pressures. Ideal for connecting simple and fast with manual tightening the instruments to be tested to the mounting. Designed for pressure gauges, pressure balances (gas and liquid medium). Related Products: Pressure Balances HDWT and PDWT, Pressure Controller DPC3800 and Pressure Gauges Holder.

• KRAC-F-1 (5 metric connectors): M10 x 100, M12 x 150, M16 x 150, M18 x 150, M20 x 150

• KRAC-F-2 (4 GAS cylinder connectors): G1/8, G1/4, G3/8, G1/2

• KRAC-F-3 (4 NPT connectors): 1/8NPT, 1/4NPT,3/8NPT,1 1/2NPT

• KRAC-F-4 (4 BSP-TR connectors): 1/8BSP-TR, 1/4BSP-TR, 3/8BSP-TR, ½ BSP-TR

Made in EU

| Datasheet | Manual |

KRAC-F-ALL – Quick Connectors Kit

Kit composed of 17 quick connectors with manual tightening

Quick connectors kit for low, medium and high pressures. Ideal for connecting simple and fast with manual tightening the instruments to be tested to the mounting. Designed for pressure gauges, pressure balances (gas and liquid medium). Related Products: Pressure Balances HDWT and PDWT, Pressure Controller DPC3800 and Pressure Gauges Holder.

KRAC-F-ALL 17 connectors:

• Cylinder connectors: M10 x 100; M12 x 150; M16 x 150; M18 x 150; M20 x 150; G1/8; G1/4; G3/8; G1/2.

• Conic connectors: 1/8 NPT; 1/4 NPT; 3/8 NPT; 1/2 NPT; 1/8 BSP-TR; 1/4 BSP-TR; 3/8 BSP-TR; 1/2 BSP-TR.

Made in EU

| Datasheet | Manual |

VP-402 – Dual Stage Vacuum Pump

Dual stage vacuum pump

Dual stage rotary vane pump with oil recycle lubrication. Check valve in the suction electrically controlled and manual ballast valve for the elimination of condensed gases.

Thanks to its high flow rate this pump can quickly reach the final vacuum drastically reducing the emptying time. Quiet and low vibration pump.

Easy installation: the light weight and the accessories (handle, base support, electric cable and switch) provide easy hand carrying for external maintenance and the compact size allows install the pump on machineries and equipment.

Reliability: all mechanical and electrical components are designed for continuous use, even 24/7.

Technical Specifications:

• Nominal flow @50Hz: 5.5 m³/h (91 l/min)

• Final Vacuum: 0.001 mbar (0.1 Pa)

• Engine Power: 240 W (0.33 CV)

• Weight: base 9.5 kg (22 lb)

• Warranty: 1 year.

Made in EU

| Datasheet | Manual |

VP-25 – Dual Stage Vacuum Pump

Dual stage vacuum pump

Ideal for laboratory applications thanks to reduced noise and the vacuum performance.

Dual stage rotary vane pump with oil recycle lubrication. Check valve in the suction electrically controlled and manual ballast valve for the elimination of condensed gases. Additional intermediate ventilation system and flanged connections Pneurop type.

Technical Specifications:

• Nominal flow @ 50Hz: 25 m³/h (420 l/min)

• Final Vacuum: 0.001 mbar (0.1 Pa)

• Engine Power: 750 W (1 CV)

• Weight: base 25.0 kg (55 lb)

• Warranty: 1 year.

Made in EU